Imagine the following scenario - your supervisor entrusts you with the task for an elastic suspension of a tank system, a cooling system, or an exhaust gas holder in such a way that as little space as possible is taken up and vibration decoupling can be carried out at the same time. However, the elements that you know and use so far are very large or not suitable for use in small and built-up rooms. Maintenance or, in the worst case, replacement in one or two years at the latest already seems problematic and you urgently want to avoid burdening your maintenance staff with this. Time is a factor either. Of course, you also have a non-stationary application and must take into account any horizontal forces, which do not occur constantly, but primarily in the form of peaks. And best of all, the vehicle drives or rolls through areas with extreme temperature differences. At first it sounds like a very long to-handle list.

The perfect solution would be a damping system that is compact and low-maintenance, limits lateral movements or, ideally, completely prevents them and still absorbs all axial vibrations, i.e. remains elastic. If it's cheap and long-lasting, everything fits together.

To be honest, we unfortunately must take away the illusion of finding such a dampener at this point. If all these points come together, the author of these lines would be blessed with a patent and long since retired. Nevertheless, there are solutions that put together a very good overall package. We would like to take a closer look at the solutions from our company here.

Our allrounder with damping characteristics in every axis

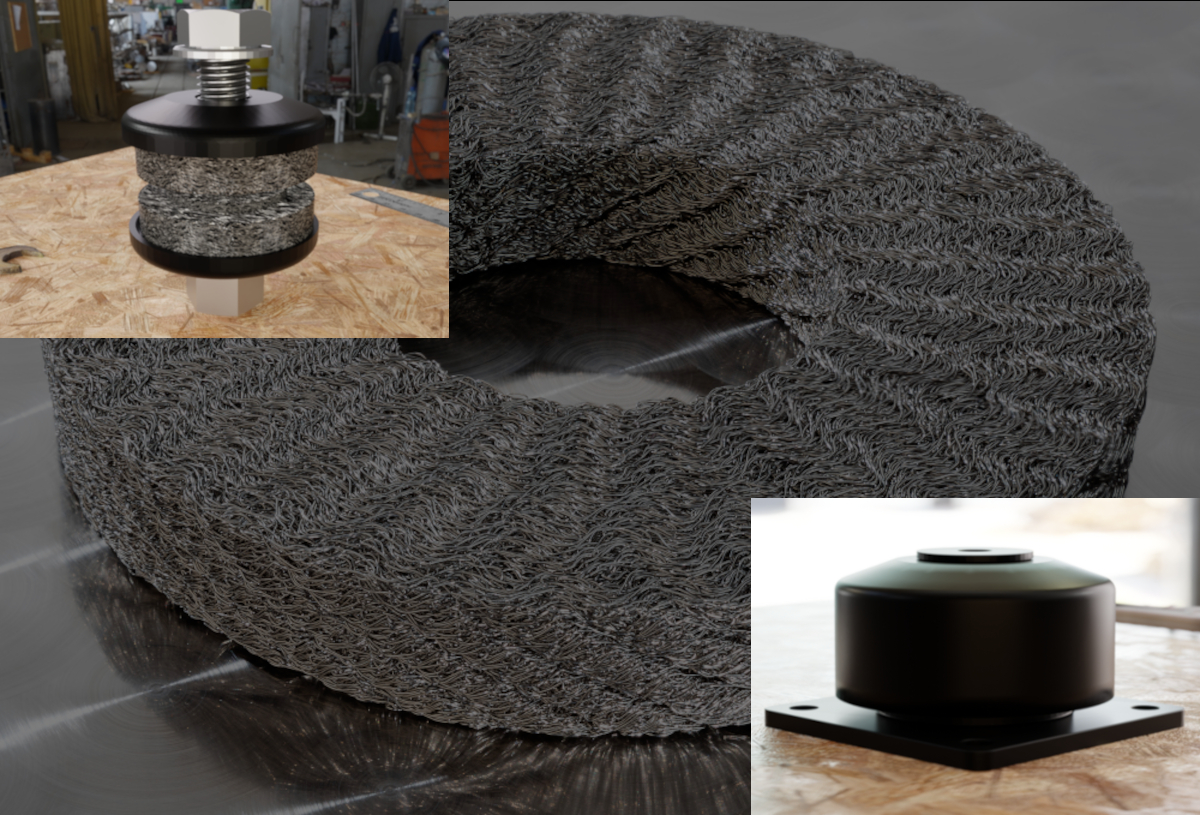

In any case, the smartest solution is always a complete assembly group. This is simply screwed under or over the respective application. Connected to the environment, it offers a decoupling of the component to be stored from the vehicle peripherals. This solution is provided by series 7 vibration dampers of the GDZ type. This type of machine base has a total of three damping cushions made of stainless-steel wire, which are encapsulated in cast steel housings. One cushion serves as a vibration damper in each direction.

Nevertheless, it can be seen from this description that this is a large type of vibration damper. Three built-in cushions with two additional housings often present the designer with the problem of small free space. Therefore it is important to find alternatives...

Pressure-tension vibration damper for small construction space

When you think of compact push-pull dampers, you quickly find damping elements from the GBL series. This type of damper only consists of two cushions, a spacer sleeve and, depending on the size, two discs or cushion seats. The two damping cushions are integrated oppositely into the profile frame of your application using the collar on the cushion. These components are screwed to the system peripherals. This results in axial decoupling from the surroundings in a manageable installation space. The damping properties of these elements in the axial direction are identical to those of the push-pull damper from the GDZ series described above. In radial direction we have no negligible damping behavior.

Pre-tension of the elements is very important

This problem is known and must be considered when designing these elements for the respective system. To avoid horizontal movement, a spacer sleeve is integrated into each collar bearing. On the one hand, this has the task of keeping the damping cushion away from the screw, and on the other hand, it serves as a mechanical stop when assembling the elements.

However, the most important point in the design is the preload specified by the sleeve and thus the force that lies on the damping elements from the start. This force is passed on as surface pressure to the system to be supported and, if correctly dimensioned, prevents slipping in the lateral direction even under high loads.

The sleeve length is determined using the load deflection diagrams in the axial direction and the thickness of the profile frame. The preload is determined using these two components and validated in internal tests. This ensures that axial damping is provided and slipping in radial direction is prevented.

Installation versus economics

At first it sounds like a sensible solution, especially for small installation spaces. In addition, the costs are relatively manageable thanks to the installed DIN parts and additional sleeves, which usually consist of standardized pipe sections. This makes vibration dampers from the GBL series attractive in terms of price, in contrast to the larger elements from the GDZ series. For example, a flange bearing for a support force of 300 kg is cheaper by a factor of 0.66 compared to a compression damper with the same load range. However, storage elements of the GBL type are currently only available up to a static load of two tons. Vibration dampers of the GDZ type are available with a static load of up to seven tons per element.

On the other hand, we have several individual components for the collar bearing vibration damper, while the multidirectional vibration damper is delivered as a single assembly and can be connected directly to the system and the peripherals without many steps. The pure assembly effort is therefore limited to a very small extent and the risk of losing individual parts is limited to a minimum.

So, which vibration damper should I choose?

In the end the all-important question arises for the designer – which type of damper is the right one for the application to be mounted? We cannot give you a general answer to this question at this point, as it depends very much on your installation space, the existing environmental conditions and of course the budget. Nevertheless, both types of dampers have already proven themselves in practice and are very successful in extending the service life of the components to be stored, especially in vehicle construction.

Bochum, 29.11.2023